Halol, Panchmahal, Gujarat

- GST NO. : 24AAACG8437C1ZX

1 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| The Length Can Be Made | Up to 12 M. |

| Slot Size May Be | 0.1 Mm to 3.0 Mm. |

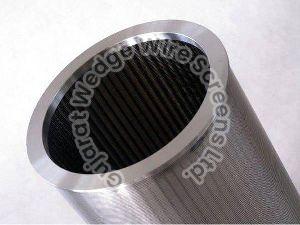

| Tube Diameter | 25 Mm - 1500 Mm. |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

When you require the most effective method to remove solids, trust our ClearBlu wedge wire waterfall systems. View five reasons our products are the best.

GWWSL manufacturers wedge wire waterfall screens as a highly efficient and cost-effective alternative to other solids removal systems. A number of factors make these wedge wire screens an excellent choice.

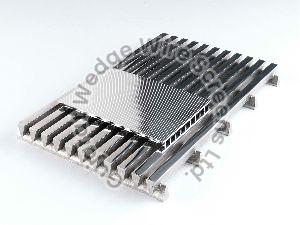

Wedge wire screen

- The wedge wire screens have a very steep angle. This allows water flow to push screened material off into a dewatering hopper.

- .5 mm screens will actually separate material as small as .25 mm.

- Automatic spray bars keep dried material from clogging the wedge wire screens. Because they are timer activated, they use 90% less water than rotary screens.

- Stainless steel construction means acidic wastewater is no challenge.

- Screening solids before pH balancing can reduce chemical consumption by 60%. Solids can soak up significant amounts of the chemical.

Models

0-150 GPM Wedge Wire Screen

This wedge wire screen is designed for flows from 0 to 100 GPM for hydro screens. GWWSL screens are unique in that they have a 60-degree slope and are self-cleaning in most applications. They have no moving parts. The concept is simple: run the wastewater over a weir and down over a wedge wire screen. The solids are pushed off the screen and the liquids pass through the wedge wire.

Wedge wire screen

There are several important factors in selecting a good waterfall filter. First, the spacing between the wedge wire bars can vary. Second, the top of the wedge wire is flat (wedge wire is made of flattened tubing) and the tops should be canted slightly so that they trap the water. Third, there needs to be sufficient runway at the top so that the water can gain velocity. This is accomplished by placing a smooth section of stainless just below the weir at the top. Fourth, the slope of the wedge wire needs to be steep. This is counterintuitive. It would seem that you would want a low slope to slow the water. Instead, you want a steep slope so that you don't build up solids on the wedge wire screen. Water is heavy and will pass through a steep screen. Manufacturer: MiTM

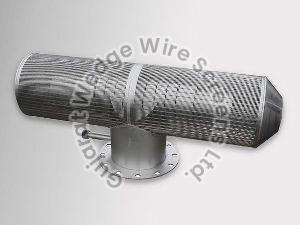

Waterfall screen

150 to 250 GPM Wedge Wire Screen

The Model 2 waterfall screen has six square feet of wedge wire screen surface and is half the size of the Model 3. This wedge wire screen effectively removes solid particles from a waste stream. Like the other types, this model uses very little energy and requires only a minimum amount of maintenance. It's ideal for many different applications including agriculture and manufacturing.

400 GPM Wedge Wire Screen

This unit will handle flows up to 400 gallons per minute. It has a 1 MM wedge wire screen. The key to hydro screens is having the correct angle on the screen and having enough runway for the water so that it gains sufficient velocity over the wedge wire screen. This seems counterintuitive. Most manufacturers lower the slope and try to slow the water. This creates clogging and water bypass.

Our unit has a 60-degree slope. The screen is 48" wide and 36" long. The unit is stainless steel.

Wedgewire Waterfall Screens

Waterfall screens are ideal for effectively removing fibrous and solid particles from a waste stream. An automatic self-cleaning spray bar runs on a timer to continually keep the screen free from debris buildup. These screens use very little energy and require very little maintenance.

Applications:

- Wineries

- Breweries

- Food Processors

- Agricultural

- Industrial (garbage companies,municipal yards, etc)

Wedgewire waterfall screens are available in three sizes:

- Number One, 0-65 GPM

- Number Two, 65-150 GPM

- Number Three, 150-300 GPM.

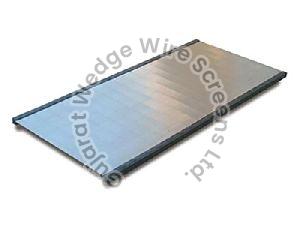

Standard wedge wire is available in 0.5 mm and 1 mm spacing, but custom spacing is available. All models are available with stands in carbon or stainless steel. For solids handling, self-dumping dewatering hoppers from ¼ yard to 5 yards in size are available. Dewatering screens are stainless steel mesh behind stainless steel perf plate with ½" openings. The hopper is carbon steel with an option to come painted or galvanized.

Looking for "Wedge Wire Screen" ?

Explore More Products